True/False

Indicate whether the

statement is true or false.

|

|

|

1.

|

Gears provide a slip action as a means to transmit power.

|

|

|

2.

|

Gears can be used on multiple shafts.

|

|

|

3.

|

Ferrous materials contain iron.

|

|

|

4.

|

Gears must have the same diametral pitch in order to mesh.

|

|

|

5.

|

Simplicity in design and manufacturing make spur gears an economical type of

gear.

|

|

|

6.

|

A worm gear can be used to hold a load or prevent a system from

reversing.

|

|

|

7.

|

Gear alignment isn’t important.

|

|

|

8.

|

A gearbox is considered a speed reducer.

|

Modified True/False

Indicate

whether the statement is true or false. If false, change the identified word or phrase to make the

statement true.

|

|

|

9.

|

Helical gears are an improved variation of a spur gear.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

10.

|

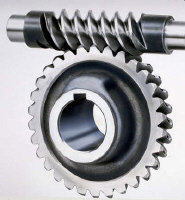

This is a __________ gear.  a. | helical | c. | bevel | b. | worm | d. | spur |

|

|

|

11.

|

This is a __________ gear.  a. | helical | c. | bevel | b. | worm | d. | spur |

|

|

|

12.

|

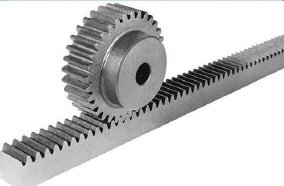

This is a __________ gear.  a. | helical | c. | bevel | b. | worm | d. | spur |

|

|

|

13.

|

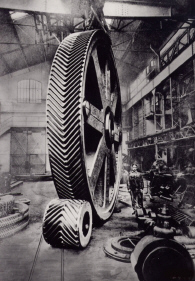

This is a ________ gear.  a. | herringbone | c. | double helical | b. | helical | d. | rack |

|

|

|

14.

|

This is a ________ gear.  a. | herringbone | c. | double helical | b. | helical | d. | rack |

|

|

|

15.

|

This is a ________ gear.  a. | herringbone | c. | double helical | b. | helical | d. | rack |

|

|

|

16.

|

This is a ________ gear.  a. | herringbone | c. | double helical | b. | helical | d. | rack |

|

|

|

17.

|

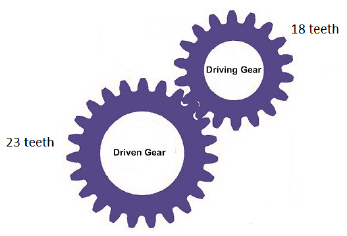

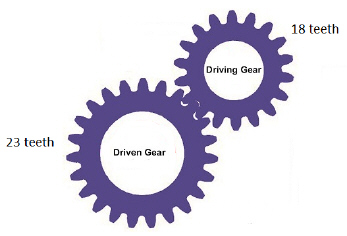

Use the gears below to calculate the output (driven) speed if the driver speed

is 1600RPM.  a. | 2048 RPM | c. | 1250 RPM | b. | 28,800 RPM | d. | 36,800 RPM |

|

|

|

18.

|

Use the gears below to calculate the output (driven) torque if the driver torque

is 500ft-lbs.  a. | 390.625 ft-lbs | c. | 9,000 ft-lbs | b. | 640 ft-lbs | d. | 11,500 ft-lbs |

|

|

|

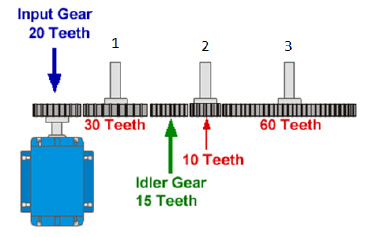

19.

|

What is the gear ratio at shaft 2?  a. | 20/10 | c. | 30/10 | b. | 60/10 | d. | 10/20 |

|

|

|

20.

|

What is the compound gear ratio?

|

|

|

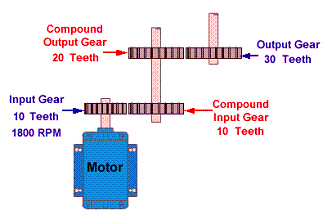

21.

|

What is the overall output torque?  a. | 114 in-lbs | c. | 1136 in-lbs | b. | 787 in-lbs | d. | 165 in-lbs |

|

Completion

Complete each

statement.

|

|

|

22.

|

___________ are toothed machine parts, such as a wheel or cylinder, that mesh

with another toothed part to transmit power and to change speed or direction.

|

|

|

23.

|

When two gears with differeing numbers of teeth are used in a drive, the gear

with the lesser number of teeth is call the ________.

|

|

|

24.

|

_________ gear trains are two gears mounted on a common shaft meshing with other

gears.

|

|

|

25.

|

Materials such as brass, composite fibers, or plastics are considered _________

materials.

|

|

|

26.

|

Materials such as steels and alloy irons are considered ________

materials.

|

|

|

27.

|

The shape and ______ of gear tooth is critical to how it handles the various

loads that are acting on it.

|

|

|

28.

|

The __________ pitch of a gear is the number of teeth in the gear for each inch

of pitch diameter.

|

|

|

29.

|

Because of the significant amount of friction generated by the sliding action of

spur gears meshing, they are used in _________ to moderate speed applications.

|

|

|

30.

|

Spur gears may have teeth that are external, internal, or on a ______.

|

|

|

31.

|

The _________ is a cylinder with threads cut on the outside.

|

|

|

32.

|

________ gears are cut on cones and usually operate on shafts at 90

degrees.

|

|

|

33.

|

__________ ___________ gears have a set of right

and left hand teeth on the same gear separted by a space.

|

|

|

34.

|

A ______________ gear has left and right teeth that join in the center to

form and apex.

|

|

|

35.

|

__________ ___________ is defined as the distance between the

tips of the pinion teeth and roots of the ring gear teeth.

|

|

|

36.

|

A gear’s function is to transmit torque and ________ motion between the

prime mover and driven equipment.

|

|

|

37.

|

A ________ ___________ that has

not been properly installed, aligned, and maintained will have a shortened life.

|

|

|

38.

|

___________ is a general term used to describe a somewhat uniform loss of

material from the contacting surface of the gear tooth.

|

|

|

39.

|

Enclosed gear drives, known as ____________ or speed reducers, are gears that

are mounted on shafts supported by bearings, and enclosed and sealed in a case.

|

|

|

40.

|

___________ gearboxes use internal gears to transmit loads in a compact space

with shafts in the line.

|

|

|

41.

|

___________ of all rotating elements is needed to prevent seizing and

overheating within the unit.

|

Matching

|

|

|

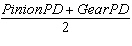

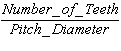

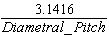

a. | Diametral Pitch | c. | Standard Center Distance | b. | Circular

Pitch |

|

|

|

42.

|

|

|

|

43.

|

|

|

|

44.

|

|

|

|

a. | Center distance | f. | Clearance | b. | Backlash | g. | Circular Pitch | c. | Diametral

Pitch | h. | Pressure

Angle | d. | Addendum | i. | Dedendum | e. | Modular Gearing |

|

|

|

45.

|

Related to the shape of the gear tooth.

|

|

|

46.

|

The measurable space at the pitch circle between two meshing gears on the

nondriving side of the face.

|

|

|

47.

|

The radial distance between the top of the tooth of the pinion and the bottom

of a tooth of the gear.

|

|

|

48.

|

The ratio of the pitch diameter in millimeters to the number of teeth in the

gear.

|

|

|

49.

|

The distance from a point on a gear tooth to a corresponding point on the next

tooth, measured along the arc of the pitch circle.

|

|

|

50.

|

The height of the tooth above the pitch circle.

|

|

|

51.

|

The distance between nonintersecting axes of the mating gears.

|

|

|

52.

|

The number of teeth in the gear for each inch of pitch diameter.

|

|

|

53.

|

The depth of the tooth below the pitch circle.

|

|

|

a. | Service Factor | f. | Gearbox Ratio | b. | Thermal Rating | g. | Horsepower and Torque

Capacity | c. | Backstops | h. | Thrust Loads | d. | Efficiency | i. | Mechanical rating | e. | Overhung

Load |

|

|

|

54.

|

Mechanisms installed as part of the gearbox to prevent reverse rotation of the

shafts.

|

|

|

55.

|

A right angle load applied to the input and output shafts of the gearbox

through a connected component.

|

|

|

56.

|

The power delivered out divied by the input power multiplied by 100.

|

|

|

57.

|

Part of the selection procedure for gearboxes.

|

|

|

58.

|

The maximum power or torque a speed reducer can transmit, based on the strength

of its parts.

|

|

|

59.

|

The maximum power or torque that can be transmitted continuously through a

drive, based on its ability to dissipate the heat generated internally.

|

|

|

60.

|

The ability to transmit the horsepower of the prime mover.

|

|

|

61.

|

Input speed divided by the output speed.

|

|

|

62.

|

Loads that are imposed on gearboxes that are paralled to their axes.

|