True/False

Indicate whether the

statement is true or false.

|

|

|

1.

|

There are three principle types of shaft couplings, rigid, flexible, and

universal joints.

|

|

|

2.

|

Rigid shaft couplings are used when a fixed union is required to connect two

rotating shafts.

|

|

|

3.

|

Shock and intermittent transient loads can damage connected equipment unless

dampened.

|

|

|

4.

|

A single type Universal Joint will accommodate angular misalignment but not

parallel/offset misalignment.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

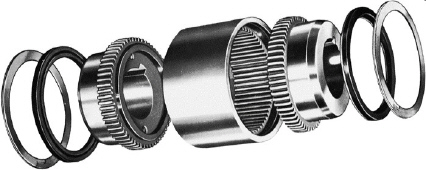

5.

|

This is a ___________.  a. | Rigid Sleeve Coupling | c. | Ribbed Rigid Coupling | b. | Flanged Rigid

Coupling | d. | Flex

Coupling |

|

|

|

6.

|

This is a ___________.  a. | Rigid Sleeve Coupling | c. | Ribbed Rigid Coupling | b. | Flanged Rigid

Coupling | d. | Flex

Coupling |

|

|

|

7.

|

This is a ___________.  a. | Rigid Sleeve Coupling | c. | Ribbed Rigid Coupling | b. | Flanged Rigid

Coupling | d. | Flex

Coupling |

|

|

|

8.

|

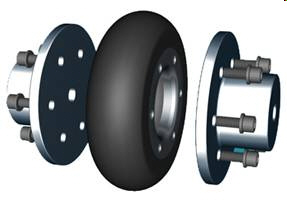

This is a _____________.  a. | Jaw Coupling Cushion | c. | Flexible Sleeve Coupling | b. | Jaw

Coupling | d. | Tire

Coupling |

|

|

|

9.

|

This is a _____________.  a. | Jaw Coupling Cushion | c. | Flexible Sleeve Coupling | b. | Jaw

Coupling | d. | Tire

Coupling |

|

|

|

10.

|

This is a _____________.  a. | Jaw Coupling Cushion | c. | Flexible Sleeve Coupling | b. | Jaw

Coupling | d. | Tire

Coupling |

|

|

|

11.

|

This is a _____________.  a. | Jaw Coupling Cushion | c. | Flexible Sleeve Coupling | b. | Jaw

Coupling | d. | Tire

Coupling |

|

|

|

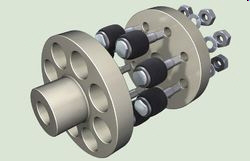

12.

|

This is a _____________.  a. | Donut Coupling | c. | Pin and Disc Coupling | b. | Pin and Bushing

Coupling | d. | Elastomeric Sleeve

Gear Coupling |

|

|

|

13.

|

This is a _____________.  a. | Donut Coupling | c. | Pin and Disc Coupling | b. | Pin and Bushing

Coupling | d. | Elastomeric Sleeve

Gear Coupling |

|

|

|

14.

|

This is a _____________.  a. | Donut Coupling | c. | Pin and Disc Coupling | b. | Pin and Bushing

Coupling | d. | Elastomeric Sleeve

Gear Coupling |

|

|

|

15.

|

This is a _____________.  a. | Donut Coupling | c. | Pin and Disc Coupling | b. | Pin and Bushing

Coupling | d. | Elastomeric Sleeve

Gear Coupling |

|

|

|

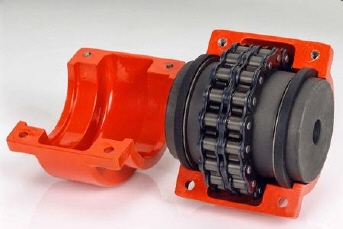

16.

|

This is a _____________.  a. | Spring Coupling | c. | Beam Coupling | b. | Chain Coupling | d. | Fluid Coupling |

|

|

|

17.

|

This is a _____________.  a. | Spring Coupling | c. | Beam Coupling | b. | Chain Coupling | d. | Fluid Coupling |

|

|

|

18.

|

This is a _____________.  a. | Spring Coupling | c. | Beam Coupling | b. | Chain Coupling | d. | Fluid Coupling |

|

|

|

19.

|

This is a _____________.  a. | Spring Coupling | c. | Beam Coupling | b. | Chain Coupling | d. | Fluid Coupling |

|

Completion

Complete each

statement.

|

|

|

20.

|

A shaft _________ is essentially a sleeve connecting two rotating shafts,

transmitting the torque from driver to driven machines.

|

|

|

21.

|

The rigid shaft coupling allows no _____________ between shafts and its use is

limited.

|

|

|

22.

|

The flexible shaft coupling sllows some _________ of the connected

shafts.

|

|

|

23.

|

Uinversal joints are used in connecting shafts that have extreme

______________.

|

|

|

24.

|

__________ shaft couplings are designed to flex under the various loads acting

on them.

|

|

|

25.

|

A _________ coupling has a spacer of different standardized lengths added into

the unit to bridge the gap between shaft ends.

|

|

|

26.

|

____________ stiffness is a resistance to twisting action between driving and

driven halves of coupling.

|

Matching

|

|

|

a. | Ribbed Rigid Couplings | c. | Flanged Rigid Couplings | b. | Rigid Sleeve

Couplings |

|

|

|

27.

|

Couplings that have halves that are split vertically and bolted

together.

|

|

|

28.

|

Couplings that have two horizontally split halves bolted together.

|

|

|

29.

|

A steel sleeve machined from a single bar, with a hole drilled in it.

|

|

|

a. | Spring Coupling | g. | Beam Coupling | b. | Fluid Coupling | h. | Pin and Bushing Coupling | c. | Pin and Disc

Coupling | i. | Gear

Coupling | d. | Donut Coupling | j. | Single Universal Joint Coupling | e. | Chain Coupling | k. | Tire Coupling | f. | Jaw

Coupling | l. | Elastomeric Sleave

Gear Coupling |

|

|

|

30.

|

Accomodates angular misalignment but not parallel/offset misalignment.

|

|

|

31.

|

A two piece apparatus consisting of an impeller and a runner contained within a

casing.

|

|

|

32.

|

Couplings that have limited misalignment capacity and low shock and vibration

dampening capability.

|

|

|

33.

|

It is sometimes refered to as the “constant velocity”

coupling.

|

|

|

34.

|

Small couplings that handle limited amounts of torque, but speeds as high as

30,000 rpm with smaller units.

|

|

|

35.

|

Couplings that are “power dense” and will handle very high amounts

of torque and horsepower.

|

|

|

36.

|

Couplings primarily used on light duty industrial applications such as the

input shaft of a fractional horsepower motor reducer.

|

|

|

37.

|

Couplings that have two hubs and a single solid flexible element.

|

|

|

38.

|

This coupling has a high capacities for misalignment. The bushings can be

made from rubber compounds, urethane or neoprene.

|

|

|

39.

|

These couplings can handle cycle loads and dampen vibration that passes through

the coupling.

|

|

|

40.

|

Couplings that accommodate significant amounts of both angular misalignment (up

to 4 degrees) and parallel/offset (up to 1/8”)

|

|

|

41.

|

One of the most common forms of nonmetallic couplings that require the use of

inserts or spiders.

|

|

|

a. | Rim/Face Alignment Method | c. | Straight Edge/Feeler Gauge/Taper

Guage Allignment Method | b. | Straight Edge Allignment

Method | d. | Single Dial

Indicator Method |

|

|

|

42.

|

Makes the alignment process less time-consuming than more sophisticated

methods.

|

|

|

43.

|

Offset and angular gaps are measured using two dial indicators.

|

|

|

44.

|

It has the advantage of being used when only one shaft can be rotated.

|

|

|

45.

|

The simplest and oldest type of alignment procedure.

|