True/False

Indicate whether the

statement is true or false.

|

|

|

1.

|

In many modern units, the clutch and brake have been combined into a single

apparatus.

|

|

|

2.

|

There are three basic application groupings for overrunning clutches:

overrunning, indexing, and backstopping.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

3.

|

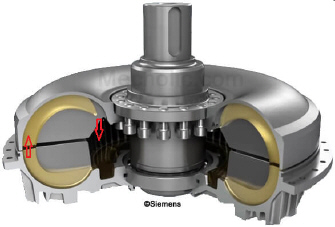

This is a  a. | Fluid Clutch | c. | Pneumatic Friction Clutch | b. | Torque Limiting

Clutch | d. | Electrical

Clutch |

|

|

|

4.

|

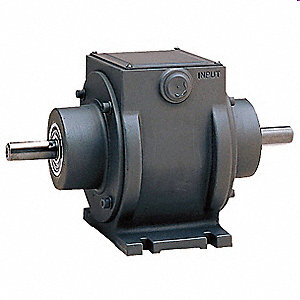

This is a  a. | Fluid Clutch | c. | Pneumatic Friction Clutch | b. | Torque Limiting

Clutch | d. | Electrical

Clutch |

|

|

|

5.

|

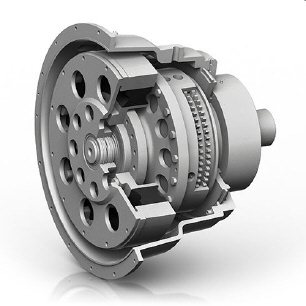

This is a  a. | Fluid Clutch | c. | Pneumatic Friction Clutch | b. | Torque Limiting

Clutch | d. | Electrical

Clutch |

|

|

|

6.

|

This is a  a. | Fluid Clutch | c. | Pneumatic Friction Clutch | b. | Torque Limiting

Clutch | d. | Electrical

Clutch |

|

Completion

Complete each

statement.

|

|

|

7.

|

Clutches, brakes, and backstops are mechanical or electrical-mechanical devices

that control energy transfer and _____________ of rotating shafts on power transmission

equipment.

|

|

|

8.

|

A major characteristic of a _________ is to connect two shafts rotating at

different speeds and to engage them smoothly until the speeds are uniform.

|

|

|

9.

|

Clutches and _______ are often used in tension-control systems where strip or

web-fed products are being wound.

|

|

|

10.

|

____________ backstops can be considered a category of their own.

|

|

|

11.

|

A _____________ is a mechanical clutch device that allows rotation in a single

direction only and is used as a safety mechanism.

|

|

|

12.

|

Backstops for light to moderate loads can be mounted internally within the

_________ on the back end of the input shaft.

|

|

|

13.

|

A ____________ is a backstop that is used on an incline conveyer application to

prevent reversal and unloading of the belt when the system is stopped.

|

Matching

|

|

|

a. | Electrical Clutches and Brakes | e. | Fluid Clutches | b. | Torque Limiting

Clutches | f. | Friction Clutches

and Breaks | c. | Positive Mechanical Clutches | g. | Overrunning Clutches | d. | Pneumatic Friction

Clutch Brakes |

|

|

|

14.

|

Use air pressure to actuate the friction discs of the clutch/break.

|

|

|

15.

|

The primary function is to allow rotation in a single direction only to prevent

reverse rotation.

|

|

|

16.

|

There are two basic forms, radial and axial and they rely on frictional forces

to function.

|

|

|

17.

|

Used as overload protection devices in mechanical power transmission

systems.

|

|

|

18.

|

Main purposes include: soft start, delayed engagement, reduced load starting,

and overload protection.

|

|

|

19.

|

Eddy current, magnet particle, and elctrically activated friction disc

clutch/breaks are all mechanisms that use electricity to activate the unit or provide the holding

power through magnetic fields.

|

|

|

20.

|

Depend on interlocking mechanical parts to transfer power from one shaft to

another.

|

|

|

a. | Ramp Clutch | c. | Sprag Clutches | b. | Pawl and Ratchet Clutch | d. | Wrap Spring

Clutch |

|

|

|

21.

|

When reverse torque is applied to either hub, the spring tightens on the hub

surface and prevents reversed turning.

|

|

|

22.

|

Incorporate specifically shaped locking cams positioned between steel rings

that allow only single direction rotation.

|

|

|

23.

|

Uses spring rollers or balls that rotate on hardened steel ramps. The

rotational torque produces a wedging action to prevent reverse rotation.

|

|

|

24.

|

The special shape of the ratchet teeth will allow the pawl to catch on the

backside of the teeth if it attemps to reverse direction.

|