True/False

Indicate whether the

statement is true or false.

|

|

|

1.

|

Leonardo da Vinci sketched a variety of different types of chains.

|

|

|

2.

|

During operation a phenomenon known as “chordal action” occurs in a

chain drive system because the chain link is a straight-line segment trying to follow the circular

path of the sprocket.

|

|

|

3.

|

There is a variety of different types of chain employed for both the purposes of

transmitting power and conveying.

|

|

|

4.

|

Sprockets do not have standard hub sizes.

|

|

|

5.

|

A maximum of 80 pitches is and appropriate center distance for most

applications.

|

|

|

6.

|

The recommended minimum teeth on a small sprocket for high speed applications is

17 teeth.

|

|

|

7.

|

Proper tension for drive chain is extremely important.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

8.

|

These are “engineered class” chains.

a. | O-Ring Chains | c. | Double Pitch Chains | b. | Roller Chains | d. | Pintle Chains |

|

|

|

9.

|

These chains are designed for power transmission or conveying service.

a. | Mill Chains | c. | Self-Lubricating Chains | b. | Offset Sidebar

Chains | d. | Double Pitch

Chains |

|

|

|

10.

|

This is a ________ chain.  a. | Roller Chain | c. | Silent Chain | b. | Leaf Chain | d. | Drag Chain |

|

|

|

11.

|

This is a ________ chain.  a. | Roller Chain | c. | Silent Chain | b. | Leaf Chain | d. | Drag Chain |

|

|

|

12.

|

This is a ________ chain.  a. | Roller Chain | c. | Silent Chain | b. | Leaf Chain | d. | Drag Chain |

|

|

|

13.

|

This is a ________ chain.  a. | Roller Chain | c. | Silent Chain | b. | Leaf Chain | d. | Drag Chain |

|

|

|

14.

|

This is a ________ chain.  a. | Mill Chain | c. | Pintle Chain | b. | Offset Sidebar Chain | d. | Double Pitch

Chain |

|

|

|

15.

|

This is a ________ chain.  a. | Mill Chain | c. | Pintle Chain | b. | Offset Sidebar Chain | d. | Double Pitch

Chain |

|

|

|

16.

|

This is a ________ chain.  a. | Mill Chain | c. | Pintle Chain | b. | Offset Sidebar Chain | d. | Double Pitch

Chain |

|

|

|

17.

|

This is a ________ chain.  a. | Mill Chain | c. | Pintle Chain | b. | Offset Sidebar Chain | d. | Double Pitch

Chain |

|

|

|

18.

|

Which type of chain would be best for transfering power under shock

loads?

a. | Leaf Chains | c. | Pintle, Mill, and Drag Chains | b. | Roller

Chains | d. | Double Pitch

Chains |

|

|

|

19.

|

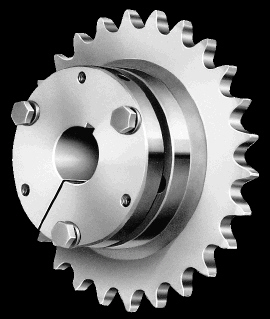

This is a type ____ sprocket.

|

|

|

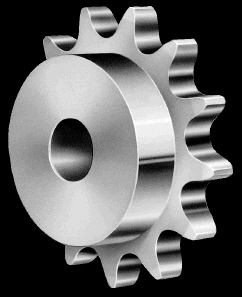

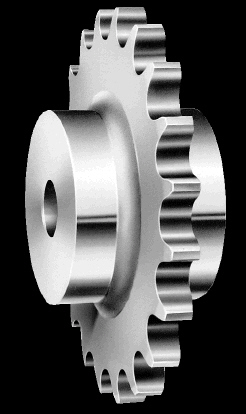

20.

|

This is a type ____ sprocket.

|

|

|

21.

|

This is a type ____ sprocket.

|

|

|

22.

|

This is a type ____ sprocket.

|

Completion

Complete each

statement.

|

|

|

23.

|

The ______ drive system consists of a driving sprocket, one or more driven

sprokets, and an endless chain consisting of individual links connected to form a strand.

|

|

|

24.

|

A _______ is a wheel that has evenly spaced, uniformly shaped teeth on the

outside diameter that provide positive engagement with the chain.

|

|

|

25.

|

Power, originating as ________, is transmitted from the drive sprocket mounted

on the shaft of the prime mover and connected to one or more driven sprockets by the chain.

|

|

|

26.

|

_________ drive chain is essentially a connected series of bearings articulating

around an axis point.

|

|

|

27.

|

Roller chains that are used for _________ handling are available with numerous

types of attachments for moving different kinds of products.

|

|

|

28.

|

___________ chains are constructed by placing joined plastic table tops onto a

base roller chain to form a two-piece construction.

|

|

|

29.

|

___________ usually consist of the body (plate), rim (teeth), and a hub that

isattached to a shaft by some means.

|

|

|

30.

|

_________ Sprockets are used to control tension and to prevent whipping on

vertical drives and long spans.

|

|

|

31.

|

A center distance of ___ to 50 pitches is good design practice.

|

|

|

32.

|

In a slow speed application, 12 teeth; for a medium speed, ____ teeth; and for

high-speed applications, 25 teeth.

|

|

|

33.

|

Drives should be inspected after the initial 100 hours of operation, followed by

_____ hour interval checks.

|

|

|

34.

|

The recommended maximum ratio under normal operating conditions is ____ for a

single reduction drive.

|

|

|

35.

|

Sprocket axial alignment can be checked with a ____________ placed across the

faces of the sprocket plates.

|

|

|

36.

|

Calculate the chain length for the following chain drive, PD1=4 inches, PD2=8

inches and CD=28 inches.

|

|

|

37.

|

Check the chain tension so that the slack side span has ___ to 6% midspan

movement in horizontal drives and 2 to 3% movement in vertical drives.

|

|

|

38.

|

The purpose of lubrication is to ______ wear between moving parts.

|

|

|

39.

|

The type of lubrican applied should be a good grade of clean __________ oil with

few additives, and free flowing at the prevailing temperatures.

|

Matching

|

|

|

a. | O-ring chain | d. | Double Pitch Roller Chain | b. | Multiple Strand

Roller Chain | e. | Roller

Chain | c. | Self-Lubricating Roller Chain | f. | Heavy Series Roller

Chain |

|

|

|

40.

|

Similar to standard roller chain, except that the pitch is twice as

long.

|

|

|

41.

|

Has oil impregnated bushings.

|

|

|

42.

|

Have pitches and part numbers similar to standard chain, but they have thicker

side plates.

|

|

|

43.

|

The most common type of chain used in industry.

|

|

|

44.

|

Made up of two or more strands, is constructed with common pins across the full

width.

|

|

|

45.

|

Designed for applications that do not permit adequate lubrication.

|

|

|

a. | Shear Pin Sprocket | c. | Split Sprocket | b. | Double Pitch Sprockets | d. | Sectional Rim

Sprockets |

|

|

|

46.

|

The rim can be replaced without distrubing the chain.

|

|

|

47.

|

A sprocket that is free to rotate on the shaft or hub when the shear pin

breaks.

|

|

|

48.

|

Sprockets for applications that require mounting between bearings, or in a

“trapped” location.

|

|

|

49.

|

Sprockets that are made to run with long pitch engineering class

chains.

|

|

|

a. | Bath, Disc, or Slinger Lubrication | c. | Manual and Drip Feed

Lubrication | b. | Oil Steam Lubrication |

|

|

|

50.

|

Method of forced lubrication.

|

|

|

51.

|

Requires that the lower strand of the chain is run through a sump of

oil.

|

|

|

52.

|

Oil is applied perodically with a brush, spout, or drip mechanism.

|