True/False

Indicate whether the

statement is true or false.

|

|

|

1.

|

On systems that must maintain positive speed, synchronous belts, rather than

V-belts drives should be used.

|

|

|

2.

|

A V-belt is considered a relatively efficient means of power

transmission.

|

|

|

3.

|

The transmission of power by yhe V-belt drive depends on effective tension or

net pull.

|

|

|

4.

|

A V-belt is a toothed drive that doesn’t slip.

|

|

|

5.

|

When using V-belts, higher speed means more net pull.

|

|

|

6.

|

Idelers should be avoided because they have a tendency to shorten belt life and

reduce power ratings.

|

|

|

7.

|

Belt drives use sprockets to pull the belt.

|

|

|

8.

|

Sheave alignment is not critical for the drive to run trouble-free.

|

Multiple Choice

Identify the

choice that best completes the statement or answers the question.

|

|

|

9.

|

V-belts that are used for light duty service.

a. | Classical | c. | Fractional Horsepower | b. | Notched | d. | Banded |

|

|

|

10.

|

V-belts that can referred to as an industrial standard.

a. | Classical | c. | Fractional Horsepower | b. | Notched | d. | Banded |

|

|

|

11.

|

V-belts that can relieve bending stress.

a. | Classical | c. | Fractional Horsepower | b. | Notched | d. | Banded |

|

|

|

12.

|

V-belts that are joined together.

a. | Classical | c. | Fractional Horsepower | b. | Notched | d. | Banded |

|

|

|

13.

|

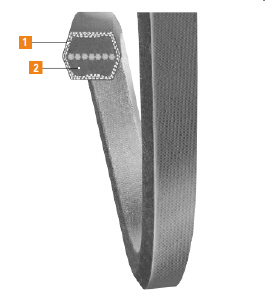

This is a ________________.  a. | V-Ribbed Belt | c. | Synchronous Belt | b. | V-Belt | d. | Flat Belt |

|

|

|

14.

|

This is a ________________.  a. | Notched V-Belt | c. | Synchronous Belt | b. | V-Belt | d. | Banded V-Belt |

|

|

|

15.

|

This is a ________________.  a. | Notched V-Belt | c. | Synchronous Belt | b. | V-Belt | d. | Banded V-Belt |

|

|

|

16.

|

This is a ________________.  a. | Notched V-Belt | c. | Synchronous Belt | b. | V-Belt | d. | Banded V-Belt |

|

|

|

17.

|

This is a ___________.  a. | Classical V-Belt | c. | Double Angle V-Belt | b. | Narrow Section V-Belt | d. | Notched V-Belt |

|

|

|

18.

|

This is a ________________.  a. | V-Ribbed Belt | c. | Synchronous Belt | b. | V-Belt | d. | Flat Belt |

|

Completion

Complete each

statement.

|

|

|

19.

|

The modern V-Belt drive was developed in the early twentieth century as a means

to transmit ________ safely and efficiently.

|

|

|

20.

|

The advantages of V-belt drives include low relative _______, quiet operation,

no lubrication, energy efficiency, a broad range of available ratios and sizes, shock aborbancy, and

easy installation.

|

|

|

21.

|

A _______________ belt is a toothed drive belt that does not slip.

|

|

|

22.

|

V-belts make use of the ____________ principle of the wedge and the belt being

in tension between the driver and driven shafts.

|

|

|

23.

|

V-belts depend upon __________ contact between the sidewalls of the sheave and

belt to transmit power.

|

|

|

24.

|

What is the inside circumference of this belt?

|

|

|

25.

|

What is the top width of this belt?

|

|

|

26.

|

The “X” series is a _____________ version of the belt.

|

|

|

27.

|

V-belt _________ are grooved wheels that are designed to run with the correct

corresponding belt.

|

|

|

28.

|

The critical dimension used in identifying and sizing the sheave is the

_________.

|

|

|

29.

|

Certain sheave types called combination or “_____ ____ “ allow

more than one belt cross-section to be used.

|

|

|

30.

|

Variable speed belts have their own form of variable _______ sheaves.

|

|

|

31.

|

_____________ belt drives are referred to by a variety of names, one being a

“timing belt”.

|

|

|

32.

|

Synchronous drive belts have ______ that are accurately molded to conform with

and engage the teeth of the matinf pulleys.

|

|

|

33.

|

With a Synchronous belt, there is no ________ of the belt that would allow speed

variation and inefficiency.

|

|

|

34.

|

Calculate the belt length for a drive system that has a center distance of

36”, a large sheave with a diameter of 16” and a small sheave with a diameter of

6”. Round you answer down to the nearest whole number (don’t use a decimal)

|

|

|

35.

|

Calculate the span length for a drive system that has a center distance of

36”, a large sheave with a diameter of 16” and a small sheave with a diameter of

6”. Write your answer with one decimal place.

|

Matching

|

|

|

a. | Bearling Loads | d. | Center Distance | b. | Arc of Contact | e. | V-Belt Drive Ratio | c. | Idler |

|

|

|

36.

|

The amount of belt wrap around a sheave groove expressed in degrees.

|

|

|

37.

|

In a V-belt drive system, the distance between the centerline of the driver and

the driven shaft.

|

|

|

38.

|

The difference in diameter between the driver and driven sheeves.

|

|

|

39.

|

A combination of sheave or pulley weight and the belt pull.

|

|

|

40.

|

A belt tightening sheave or pulley on a drive to increase tension.

|

|

|

a. | Banded Belts | d. | Double Angle V-belts | b. | Narrow Section V-Belts | e. | V-Ribbed Belt | c. | Open End

Belts |

|

|

|

41.

|

A single endless rubber and fiber belt with a series of v-ribs molded

lengthwise aroun the inside circumference.

|

|

|

42.

|

Compact belts that can do more work in less space.

|

|

|

43.

|

Their shape permits them to transmit power from both the top and bottom half of

the belt.

|

|

|

44.

|

Belts designed for emergency replacement.

|

|

|

45.

|

V-belts that are joined together with a permanent tie band.

|